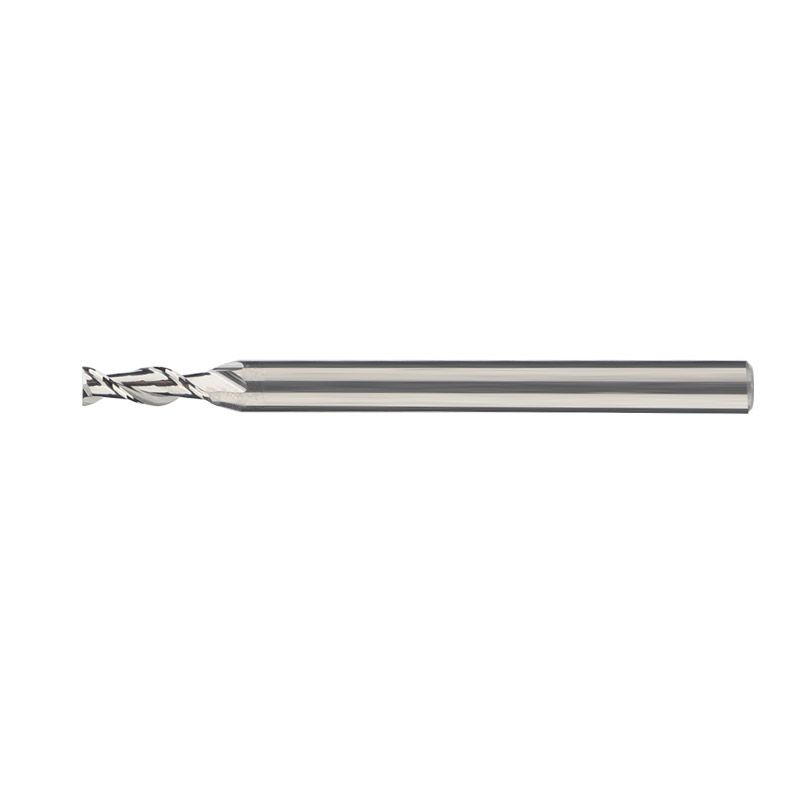

Two-point milling cutter

- Category:

Aluminum&magnesium alloy highlight series

- Number of blades:

2-blade

- Advantage:

High brightness/wear resistance

- Apply:

Copper alloy, aluminum alloy, zinc alloy and other non-ferrous metals

This two-edge milling cutter is made of tungsten steel and paired with nano coating, which has the core advantages of "smooth chip removal, sharp wear resistance, and sharp edge". Large core diameter design to enhance rigidity and shock resistance, all grinding edge to ensure sharp cutting, extend tool life; The fine grinding process makes the cutting edge without micro-imperfections, better wear resistance and precision. Round handle chamfering treatment, tight clamping without slippage, full grinding spiral groove to achieve large chip discharge, avoid sticking knife, significantly improve processing efficiency. Suitable for aluminum parts, copper parts, plastic, bakelite and other low hardness of the workpiece, suitable for CNC machining center, engraving machine and other high-speed equipment, rich specifications, to meet a variety of processing scenarios.

| Blade diameter | Blade length | Shank diameter | Overall length |

| D1 | 3 | D4 | 50L |

| D1.5 | 4.5 | D4 | 50L |

| D1.7 | 5.1 | D4 | 50L |

| D1.9 | 5.7 | D4 | 50L |

| D2.1 | 6.2 | D4 | 50L |

| D2.4 | 7.6 | D4 | 50L |

| D2.7 | 8.4 | D4 | 50L |

| D2.9 | 9.3 | D4 | 50L |

| D3.2 | 9.6 | D4 | 50L |

| D3.3 | 9.2 | D4 | 50L |

| D3.6 | 10.8 | D4 | 50L |

| D3.8 | 11.4 | D4 | 50L |

| D3.9 | 11.7 | D4 | 50L |

| D4.5 | 12 | D4 | 50L |

| D5 | 13 | D4 | 50L |

| D6.5 | 15 | D4 | 60L |

| D7.5 | 18 | D4 | 75L |

| D9.5 | 24 | D4 | 75L |

| D11.5 | 28 | D4 | 75L |

| D15 | 45 | D4 | 100L |

Related products

Coating cutter

Application: Spare parts and accessories

Ball end milling cutter

Application: Spare parts and accessories

Round nose milling cutter

Application: Spare parts and accessories

Colorful aluminum milling cutter

Application: Spare parts and accessories

65 ° blue nano coating milling cutter

Application: Spare parts and accessories