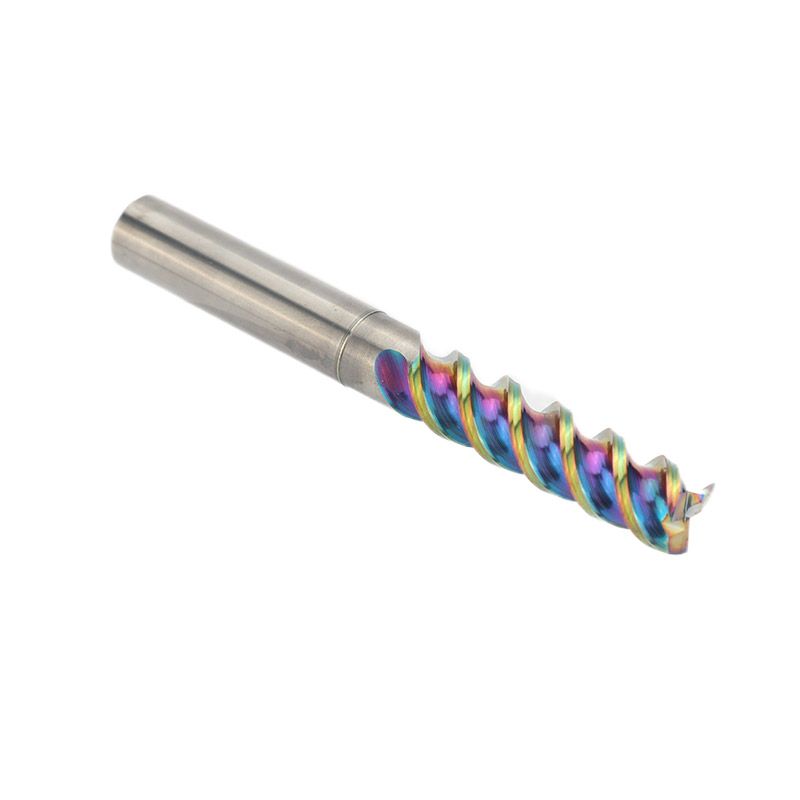

Colorful aluminum milling cutter

- Category:

Aluminum&magnesium alloy highlight series

- Number of blades:

three-blade

- Advantage:

High brightness/wear resistance

- Apply:

CNC machining center, engraving machine, engraving machine, etc

This product is a colorful aluminum milling cutter, which has significant advantages in material and process, design and function. It is made of tungsten steel and supplemented by nano coating to achieve wear-resistant and durable characteristics and ensure quality. In design, the large core structure enhances rigidity and shock resistance, and the surface is smooth and delicate. All grinding edge to ensure sharp cutting, effectively extend the service life; Different groove and spiral Angle design to meet the needs of complex production processes; Round handle chamfer design makes the clamping tight and easy to slip during operation. Functional level, large chip discharge combined with fine grinding spiral groove, effectively avoid knife sticking problems, greatly improve production efficiency, bright color high-gloss coating further help smooth chip discharge and sharp cutting edge. A wide range of applications, can process aluminum parts, copper parts, plastic, bakelite, iron parts and other low hardness of the workpiece, suitable for CNC machining center, engraving machine, engraving machine and other high-speed equipment. When using, pay attention to the swing of the tool (≤0.01mm), adjust the speed according to the extension length of the tool, retain the oxide film to protect the cutting edge during processing, it is recommended to use cutting fluid; For steel processing, fog or jet cooling is recommended to optimize the use effect.

| Blade diameter | Blade length | Handle diameter | Total length | Coating combination |

| D2 | 6 | D2 | 50L | D26D2*50L |

| D1 | 3 | D4 | 50L | D13D4*50L |

| D1.5 | 4.5 | D4 | 50L | D1.54.5D4*50L |

| D2 | 7.5 | D4 | 50L | D27.5D4*50L |

| D3 | 9 | D4 | 50L | D39D4*50L |

| D3 | 9 | D3 | 50L | D39D3*50L |

| D3 | 12 | D3 | 100L | D312D3*100L |

| D3 | 15 | D3 | 75L | D315D3*75L |

| D4 | 16 | D4 | 75L | D416D4*75L |

| D4 | 20 | D4 | 100L | D420D4*100L |

| D5 | 13 | D6 | 50L | D513D6*50L |

| D5 | 13 | D5 | 50L | D513D5*50L |

| D5 | 20 | D5 | 75L | D520D5*75L |

| D5 | 25 | D5 | 100L | D525D5*100L |

| D6 | 15 | D6 | 50L | D615D6*50L |

| D6 | 24 | D6 | 75L | D624D6*75L |

| D6 | 30 | D6 | 100L | D630D6*100L |

| D8 | 24 | D8 | 60L | D824D8*60L |

| D8 | 30 | D8 | 75L | D830D8*75L |

| D8 | 35 | D8 | 100L | D835D8*100L |

| D10 | 25 | D10 | 75L | D1025D10*75L |

| D10 | 40 | D10 | 100L | D1040D10*100L |

| D12 | 35 | D12 | 75L | D1235D12*75L |

| D12 | 45 | D12 | 100L | D1245D12*100L |

| D14 | 45 | D14 | 100L | D1445D14*100L |

| D16 | 45 | D16 | 100L | D1645D16*100L |

| D16 | 70 | D16 | 150L | D1670D16*150L |

| D20 | 45 | D20 | 100L | D2045D20*100L |

| D6 | 45 | D6 | 150L | D645D6*150L |

| D8 | 50 | D8 | 150L | D850D8*150L |

| D10 | 60 | D10 | 150L | D1060D10*150L |

| D12 | 60 | D12 | 150L | D1260D12*150L |

| D14 | 70 | D14 | 150L | D1470D14*150L |

| D16 | 75 | D16 | 150L | D1675D16*150L |

| D18 | 75 | D18 | 150L | D1875D18*150L |

| D20 | 75 | D20 | 150L | D2075D20*150L |

Related products

Coating cutter

Application: Spare parts and accessories

Ball end milling cutter

Application: Spare parts and accessories

Two-point milling cutter

Application: Spare parts and accessories

Round nose milling cutter

Application: Spare parts and accessories

65 ° blue nano coating milling cutter

Application: Spare parts and accessories